Basics GHz-Plasma

Fundamentals of Microwave Plasmas and Plasma Jets

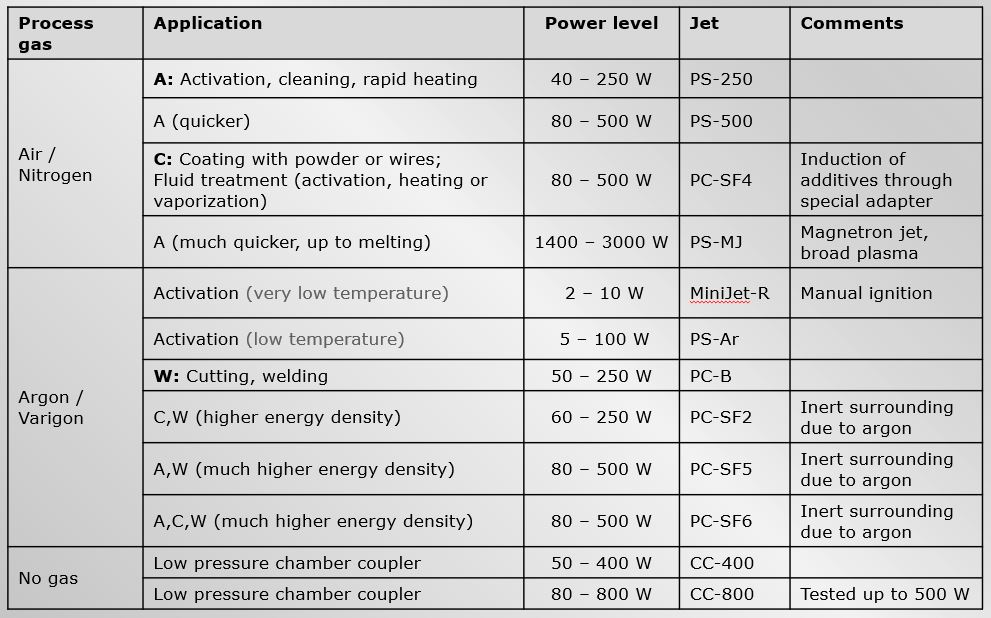

HHF’s microwave plasma jets are the first commercially available atmospheric plasma sources at 2.45 GHz in the power range between 2 W and 3000 W (on request 6000 W). These plasma jets can also be used for disinfection of CORONA conterminated surfaces. HHF offers the largest spectrum of jets to generate plasma for different applications, see Fig. 1.

These microwave plasma jets offer the well known advantages of the so-called microwave plasmas (or sometimes microplasmas), which have been verified in numerous publications. One major advantage at microwave frequencies (in contrary to other technologies) is, that here merely the electrons are accelerated as the ions are too inert to follow the alternating signals, going up from 0 V to the maximal voltage within a tenth of a nanosecond. This results in a „soft plasma“, which is much cooler than other plasmas due to the low ion acceleration. Using these jets in combination with the novel and world wide patent protected control electronic, scientist and practical users can benefit from these advantages in a number of possible applications.

With the experience of more than 12 years, HHF is the leading company in the development and manufacture of GHz plasma sources and also has by far the largest range of standard and special products.

Short overview of the features of microwave plasma jet:

-

- Pure atmospheric 2.45 GHz plasma for continuous power levels of up to 6000 W

- Applicable with nearly all gasses

- Available as stream line jet and plane jet

- Highly efficient, low loss plasma jets

- Relatively low plasma temperature since solely electrons are accelerated

- Relatively high plasma temperature at vicinity of nozzle due to high power density

- Usable by hand or robotized, genuine 100 % potential free

- Very low power consumption

- Maintenance free without wear off

- Compact, handy form and size

- Cost efficient technology, easily applicable to production facilities

- Further advantages for diverse applications presented below

Summary of Technical Backgrounds

Practically all commercially available atmospheric plasmas in the power levels of up to 20 W are produced by arcing and are stimulated by high frequency signals ranging in kHz or lower MHz regions. HHF’s microwave plasma jets are stimulated by a microwave signal at 2.45 GHz through a standard 50 ohm coaxial cable. To realize the high voltage transformation at 2.45 GHz required for the ignition, distributed coaxial elements are integrated in the microwave plasma jet. These transformation elements, made of pure metal, are placed directly at the inner electrode. The casing is absolutely free of high voltage. The microwave radiation is measureable, but well below prevailing limits. Microplasma ignition takes place in the microwave plasma jet or at the nozzle. Fig. 3 shows microwave plasma in a preliminary development stage at the Aachen University of Applied Sciences.

The fact, that microwave plasma does not discharge directly against ground, results in an absolutely potential free housing and low thermal losses. Furthermore, since the microplasma is not based on the electron emission at the electrode, but on the capacitive coupling between the electrode and the casing forming a coaxial line, the strain on the electrode is considerably lower than in the case of arcing.

Especially in case of process gases that are hard to ionize, such as air, the microwave plasma-jets demonstrate a higher degree of ionization, since the arcing manages to ionize only a small portion of the process gas. Scientific experiments carried out with merely 10 W could demonstrate the high efficiency of microplasmas in technical applications. Several spectroscopy analyses have been carried out, verifying that no electrode erosion takes place. Due to the low heating of the electrode, all HHF plasma jets are produced with maintenance free copper electrodes.

Summary of Technical Applications

Industrial and medical applications using plasmas are increasing continuously. The following are some major applications using low power levels (below 250 W):

- Activating plastic surfaces for welding, melting, painting, varnishing, printing, coating, gluing, etc. as well as further processing steps

- Cleaning von different metallic surfaces for soldering, varnishing, coating, gluing, bonding, etc. as well as further processing steps

- Disinfection and sterilization of wounds (below 20 W and Ar gas) even of instruments in medical fields or imported hardware

- Aging treatment of components

- Further applications using higher power levels (above 250 W):

- Replacing natural gas and hydrogen burners (the energy efficiency estimated by HHF is better than the hydrogen burner by a factor of 3!)

- Soft soldering and hard soldering of metals

- Amalgamation or fusing of surfaces and boring holes or vias

- Labeling or inscription of various materials

- Firing in of paint or varnish

- Cutting various materials

- Welding various materials

- Coating various materials

More Presentations of the Microwave Plasma Technology and Jets as well as whose Applications

Please find in the enclosed application note examples of the efficiency of the plasma jets from HHF: Plasma_AppNote

A scientific paper offering the plasma physics of a 2.45 GHz plasma jet is available from: https://www.researchgate.net/publication/224607487_at_245_GHz

Further background information regarding plasma technique and numerous details concerning microwave plasmas can be found in the lecture notes for „Mikrowellentechnik“ (Prof. Heuermann, Master Degree course at the Aachen University of Applied Sciences): Mikroplasma (presently only in German)

Further information available under: Info@HHFT.de.